Eminye imigca ye-extrusion yombhobho ethengiswayo

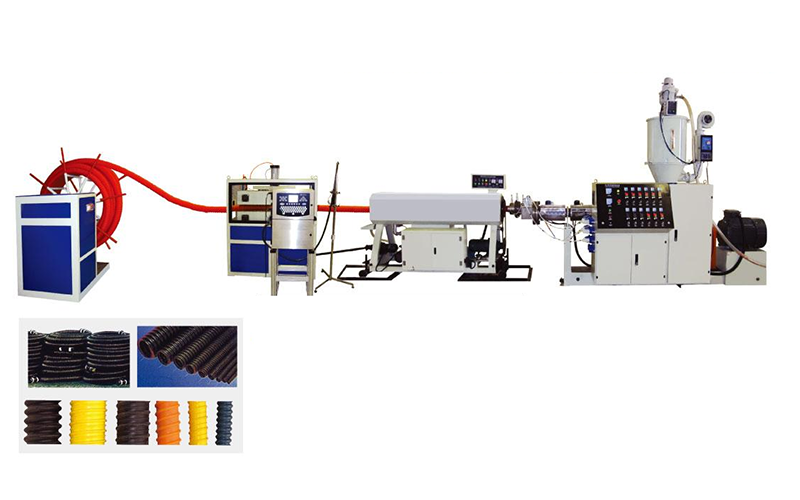

Umatshini wemibhobho yentsimbi eyomeleziweyo yocingo lwentsimbi

I-Skeleton wire skeleton eyomeleziweyo yeplastiki yombhobho edibeneyo isetyenziswa kakhulu kumashishini, ukunikezelwa kwamanzi esixeko, igesi, imichiza kunye nezolimo, njl. Inokuvelisa amanzi e-polyethylene okanye umbhobho werhasi nawo. Yinjongo ezininzi ukugcina utyalo-mali. Umbhobho unenzuzo yoxinzelelo oluphezulu, izinto ezifunekayo ngaphantsi kunye ne-unstratified, i-tec. Umgangatho wasetyenziswa waze wanyanzeliswa ngonyaka ka-2004. Imimiselo yobunjineli ehambelanayo kunye nokufakelwa kugqitywe kakuhle. Ukwenziwa, ukuthengisa kunye nokukhuthaza kuye kwamanyathelo ngamanyathelo kwindlela yophuhliso loshishino. Iba yimveliso ephambili yeepayipi ezidibeneyo.

Umhla wobugcisa

| Umzekelo | Uluhlu lwemibhobho(mm) | Isantya somgca(m/min) | Amandla oFakelo ewonke(kw |

| LSSW160 | 中50- φ160 | 0.5-1.5 | 200 |

| LSSW250 | φ75- φ250 | 0.6-2 | 250 |

| LSSW400 | φ110- φ400 | 0.4-1.6 | 500 |

| LSSW630 | φ250- φ630 | 0.4-1.2 | 600 |

| LSSW800 | φ315- φ800 | 0.2-0.7 | 850 |

| Ubungakanani bombhobho | Umbhobho oqinileyo we-HDPE | Amathambo entsimbi yentsimbi yombhobho weplastiki odityanisiweyo | ||

| Ukutyeba(mm) | Ubunzima(kg/m) | Ukutyeba(mm) | Ubunzima(kg/m) | |

| φ200 | 11.9 | 7.05 | 7.5 | 4.74 |

| φ500 | 29.7 | 43.80 | 15.5 | 25.48 |

| φ630 | 37.4 | 69.40 | 23.5 | 40.73 |

| φ800 | 47.4 | 112.00 | 30.0 | 75.39 |

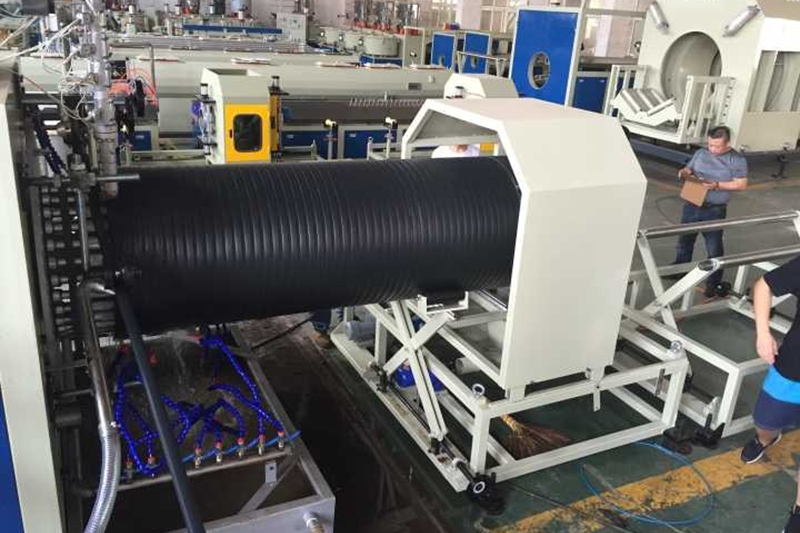

Umatshini wombhobho wokujija udonga lwe-HDPE

Umbhobho we-HDPE onomngxuma wokuvala umbhobho wodonga usetyenziselwa ukwenza imibhobho esetyenziselwa ukuhambisa amanzi kunye nogutyulo kwiindawo ezininzi, ezifana nokwakhiwa kukamasipala, izithili zokuhlala, iindlela ezinkulu kunye neebhulorho, njl.

Umbhobho wokujija eludongeni onomgongxo usetyenziswa ikakhulu kwisixokelelwano sogutyulo, ngokufanayo nombhobho wamalahle ophindwe kabini. Xa kuthelekiswa nombhobho otyatyiweyo wodonga oluphindwe kabini, ineenzuzo zexabiso eliphantsi lotyalo-mali lomatshini kunye nobubanzi bombhobho omkhulu.

Umgca wethu we-PE ogobileyo wombhobho we-extrusion unokuqhuba iindidi ezininzi zemathiriyeli, kubandakanywa i-HDPE, i-PP, njl.

Ukutshintsha amanye amalungu kunokuvelisa imilo eyahlukileyo yombhobho okanye inkangeleko yenze iindidi ezahlukeneyo zombhobho ojikelezayo.

◆I-extruder yokuqala ivelisa umbhobho woxande kumatshini ojijayo, owesibini uvelisa isivalo seplastiki, emva koko isivalo seplastiki sicinezelwe kumbhobho woxande kwaye umbhobho ojiko uphume ngaphandle.

◆Ithatha i-spiral die head kunye ne-extruder chargeing ezimbini, iqonda ukumila okujikelezayo.

◆Inkqubo yolawulo lwekhompyutha ye-PLC ephucukileyo yenza kube lula ukusebenza. Izinzileyo kwaye ithembekile.

◆ Ngoyilo olwahlukileyo lwetyhubhu yeprofayili inokuvelisa imibhobho ye-dfrerent ring stfness e-audapt todiferet iimeko kunye neefelds.

◆Isikrufu esikhulu sokusetyenziswa kwesikruru esinye (ukusebenzisa iigragrama) kunye ne-screwextruder eyonga amandla (usebenzisa umgubo okanye imathiriyeli yegranule forchoice.

◆ Ukutshintsha amanye amalungu kunokuvelisa intsimbi yesikwere proftle umbhobho ojikelezayo owomeleziweyo.

◆Uluhlu olupheleleyo lwenkcazo, uluhlu lwemibhobho: ID200mm -ID3200om

Iinkcukacha

Isikruru esiNye Extruder

Ngokusekelwe ku-33: 1 umlinganiselo we-L / D we-screw design, siye saphuhlisa umlinganiselo we-38: 1 L / D. Xa kuthelekiswa ne-33: umlinganiselo we-1, umlinganiselo we-38: 1 unenzuzo ye-100% yeplastiki, ukwandisa umthamo wemveliso nge-30%, ukunciphisa ukusetyenziswa kwamandla ukuya kuma-30% kwaye ufikelele ekusebenzeni kwe-linear extrusion.

I-Simens Touch Screen kunye ne-PLC

Faka isicelo kwinkqubo ephuhliswe yinkampani yethu, ube nesiNgesi okanye ezinye iilwimi ukuba zibe negalelo kwinkqubo.

Ukwakhiwa kwe-Spiral ye-Barel

Ukondla inxalenye yomgqomo wokusetyenziswa kwesakhiwo esijikelezayo, ukuqinisekisa ukutya kwezinto eziphathekayo ngokuzinzileyo kunye nokwandisa umthamo wokutyisa.

Uyilo olukhethekileyo lweScrew

I-Screw yenzelwe kunye nesakhiwo esikhethekileyo, ukuqinisekisa iplastiki efanelekileyo kunye nokuxuba. Izinto ezinganyibilikiyo azikwazi ukudlula le ndawo yesikrufu.

Isifudumezi seCeramic esipholileyo soMoya

Isifudumezi seCeramic siqinisekisa ubomi obude bokusebenza. Olu yilo kukwandisa indawo apho ukudibana kweheater nomoya. Ukuba nesiphumo esingcono sokupholisa umoya.

Umgangatho ophezulu weGearbox

Ukuchaneka kwegiya kufuneka kuqinisekiswe ibanga le-5-6 kunye nengxolo esezantsi engaphantsi kwe-75dB. Ulwakhiwo olubambeneyo kodwa olunetorque ephezulu.

Umatshini womoya

Umatshini wokuvala umoya usetyenziselwa ukuvuthuza umbhobho osikwere kwaye udibanise kunye ukwenza umbhobho ojikelezayo. Iyahlengahlengiswa ukuvelisa ubungakanani bombhobho ojikelezayo obahlukeneyo, kwakhona ingelosi ejijayo iyahlengahlengiswa kumbhobho wesikwere kububanzi obahlukeneyo. Ngokupholisa kwamanzi okusebenzayo.

IGlue Extruder

Nge-glue extruder ukubeka phezulu kumatshini wokujija. I-extruder inokuhamba kulo lonke icala: phambili nasemva, phezulu naphantsi, ekhohlo nasekunene. Kulula ukusebenza.

Gqibezela inkqubo yohlengahlengiso

Iseti epheleleyo yenkqubo yokuhlengahlengisa ukwenza umbhobho wesquare wenze umbhobho ojikelezayo ube lula kwaye uzinze.

Gear Drive

Sebenzisa i-gear drive, umatshini wokujija osebenza ngokuzinzileyo, ochanekileyo kwaye osebenzayo.

Siemens PLC

Faka isicelo kwinkqubo ephuhliswe yinkampani yethu, ube nesiNgesi okanye ezinye iilwimi ukuba zibe negalelo kwinkqubo.

Umsiki

I-Cutter elawulwa yi-Siemens PLC enenkqubo yokusika ngokuzenzekelayo, enokwenza ubude bokusika ngokwezifiso.

Umzila kaloliwe ochanekileyo

Faka umzila kaloliwe wesikhokelo, iitroli zokusika ziya kuhamba ngomzila kaloliwe. Inkqubo yokusika izinzile kwaye ubude bokusika buchanekile.

Umqokeleli wothuli lwamashishini

Ngomqokeleli wothuli wamashishini onamandla ukuze ukhethe ukufunxa uthuli.

Stacker

Ukuxhasa imibhobho, kunye ne-rubber support roller, i-roller iya kujikeleza kunye nombhobho.

Injini yerola

Kumbhobho omkhulu ojikelezayo, faka i-motor ukuqhuba i-roller ejikelezayo kunye nombhobho.

Uhlengahlengiso loMphakamo ophakathi

Kumbhobho omkhulu ojikelezayo, faka i-motor ukulungisa ubude obuphakathi, kulula kwaye ngokukhawuleza.

Idatha yoBugcisa

| Umzekelo | Uluhlu lwemibhobho(mm) | Umthamo wemveliso(kg/h) | Amandla ewonke(kw) | |

| ID(min) | OD(ubukhulu) | |||

| ZKCR800 | 200 | 800 | 100-200 | 165 |

| ZKCR1200 | 400 | 1200 | 150-400 | 195 |

| ZKCR1800 | 800 | 1800 | 300-500 | 320 |

| ZKCR2600 | 1600 | 2600 | 550-650 | 400 |

| ZKCR3200 | 2000 | 3200 | 600-1000 | 550 |

I-PE carbon spiral yombhobho wombhobho owomeleziweyo umgca wokuphuma

| UMZEKELO | SJ90/30 | SJ65/30B |

| UMPIPI IDAMETER | 50-200 | 20-125 |

| CALIBATE UNITHI | SGZL-200 | SGZL-125 |

| UMSHINI WOKUXHUMELA | SLQ-200 | SLQ-200 |

| UMTSHINI WOKUSOSHA | SQ-200 | SQ-200 |

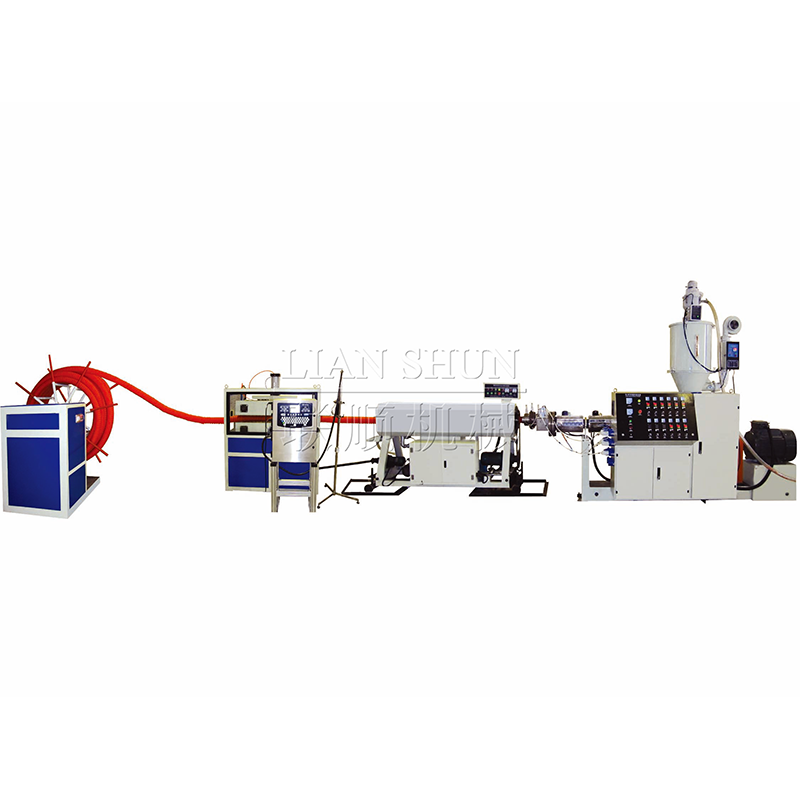

I-PVC spiral hose extrusion line

| Umzekelo | SJ45 | SJ65 |

| Extruder | SJ45/28 | SJ65/28 |

| Uluhlu lweDlameter(mm) | φ12- φ50 | φ63- φ200 |

| Imveliso(kg/h) | 20-40 | 40-75 |

| Amandla afakiweyo(kw) | 35 | 50 |

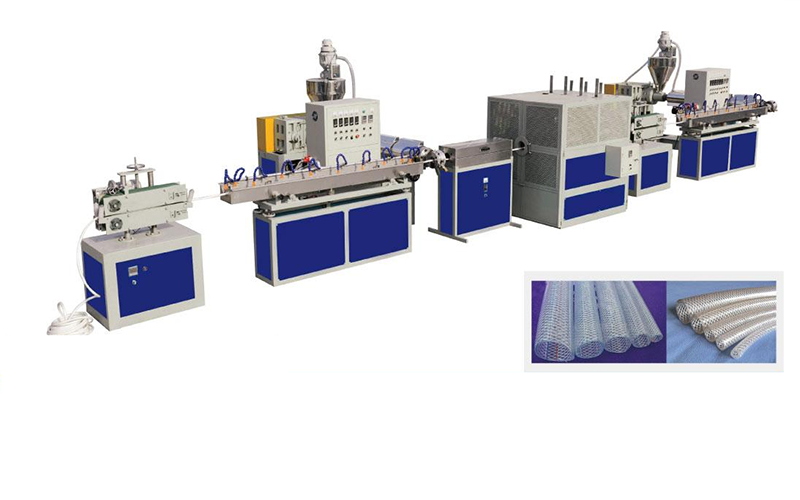

I-PVC ifayibha yokuqinisa umgca we-hose extrusion

| Extruder | Umbhobho ububanzi | Umthamo | Amandla afakiweyo | Ukusetyenziswa kwamandla okuphakathi | ubukhulu |

| SJ-45×30 | <6-25mm | 35-65kg/h | 39.9kw | 27.5kw | 1.2*3*1.4 |

| SJ-65×30 | <8-38mm | 40-80kg/h | 66.3kw | 39.78kw | 1.3*4*5 |

| i-extruder | Iyunithi yokuthuthwa | Braider | Umatshini wokupholisa | Itanki yokomisa | iwinder |

| 2 iiseti | 2 iiseti | Iseti e-1 | 2 iiseti | Iseti e-1 | Iseti e-1 |

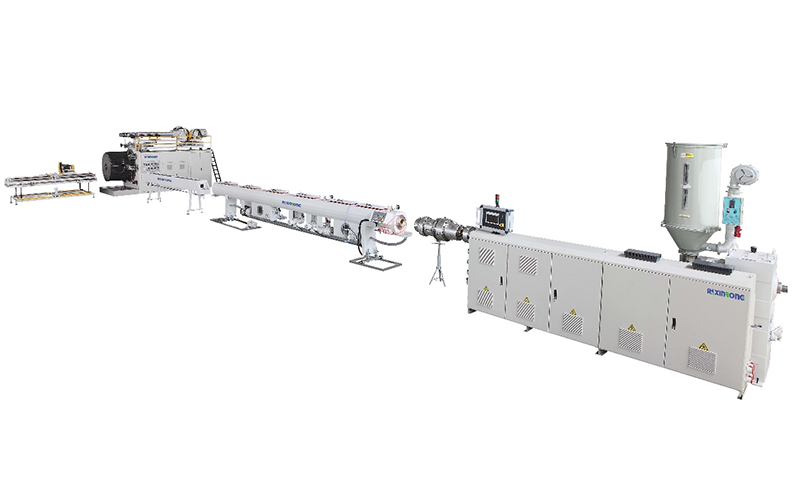

Intsimbi ye-PVC eyomeleziweyo ye-hose extrusion line

| Umzekelo | SJ45 | SJ65 | SJ90 | SJ120 |

| Extruder | SJ45/30 | SJ65/30 | SJ90/30 | SJ120/30 |

| Uluhlu lweDlameter(mm) | φ12- φ25 | φ20- φ50 | φ50- φ110 | φ75- φ150 |

| Imveliso(kg/h) | 20-40 | 40-75 | 70-130 | 100-150 |

| Amandla afakiweyo(kw) | 30 | 40 | 50 | 75 |