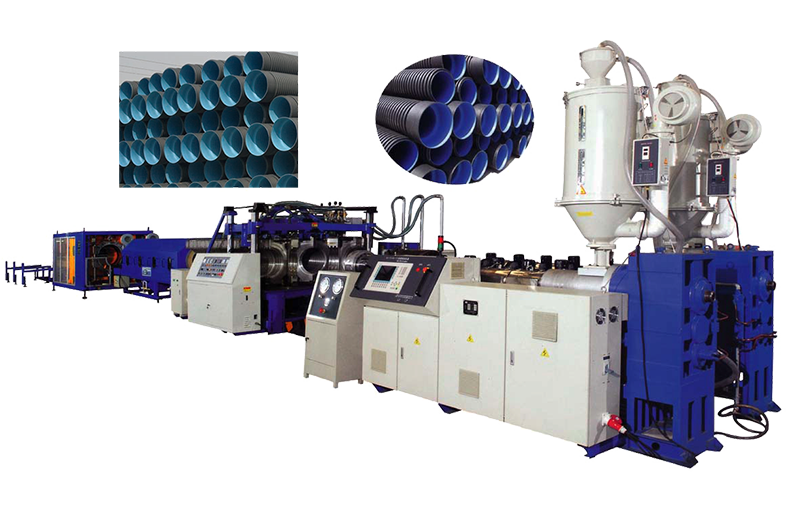

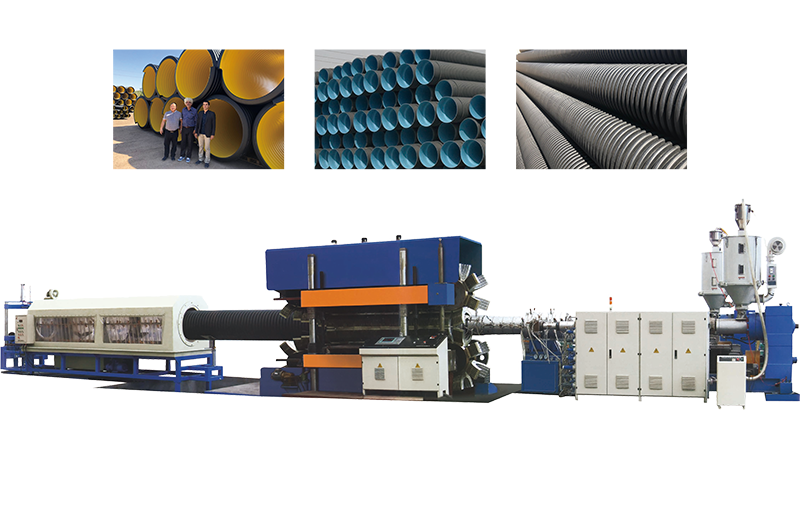

Isantya esiphezulu se-PE PP (PVC) i-Corrugated Pipe Extrusion Line

Inkcazo

Umatshini wePlastiki wamalahle usetyenziselwa ukuvelisa imibhobho yeplastiki yamalahle, esetyenziswa ikakhulu kwimijelo yasezidolophini, iinkqubo zogutyulo, iiprojekthi zohola wendlela, iiprojekthi zokunkcenkceshela zolondolozo lwamanzi kumhlaba weefama, kwaye zinokusetyenziswa kwiiprojekthi zothutho lwemichiza yolwelo, kunye noluhlu olubanzi ngokwentelekiso. Umatshini wokwenza umbhobho ogqwethiweyo uneenzuzo zemveliso ephezulu, i-extrusion ezinzileyo kunye nenqanaba eliphezulu lokuzenzekelayo. I-extruder inokuqulunqwa ngokwemiqathango ekhethekileyo yezinto zomsebenzisi, njenge-PE PP okanye i-PVC. I-PE PP yodonga oluphindwe kabini lombhobho we-extrusion line sebenzisa uhlobo olutsha lwe-high-efficiency single/twin screw extruder. PVC umatshini amacangci umbhobho sebenzisa iwele elikhulu tyaba okanye conical iwele extruder. Ngomaleko omnye kunye nemigangatho emibini yokukhetha. Ukwenza imibhobho yamacangci kabini eludongeni, kukho iindidi ezimbini;oluthe tyaba kabini eludongeni umbhobho otyatyiweyo umgca extrusionkwayeudonga oluthe nkqo kabini eludongeni olutyatyiweyo lombhobho womgca.

Inkqubo Flow

Imathiriyeli ekrwada → Ukuxuba → Isifunxi sokufunxa →Isixhobo sePlastiki seHopper →Isikhupha →Isikhuseli sokungunda →Ukwenza ukubumba → ukupholisa umatshini wokwenza umatshini →Itanki yaManzi okupholisa isitshizi →umatshini wokusika →isitaki

Iimpawu kunye nezinto eziluncedo

1. I-HDPE ithatha uhlobo olutsha lwe-high-efficiency eyodwa / i-twin screw extruder, kunye ne-PVC ithatha i-flat flat enkulu okanye i-conical twin extruder. I-extruder enkulu ye-conical-screw extruder okanye i-parallel-screw extruder inokubona iplastiki egqwesileyo kubushushu obuphantsi kunye ne-extrusion ezinzileyo.

2. Indlela yokupholisa imodyuli iphoqelelwe ukupholisa kwamanzi, okuphucula kakhulu isantya sokupholisa imodyuli, ukuze kuphunyezwe imveliso yesantya esiphezulu.

3. Umgca wombhobho odibeneyo ubizwa ngokuba yi-double wall corrugated pipe machine line inokuqonda ukuvutha kwe-intanethi ukuqinisekisa ukuba iipropati ezahlukeneyo zombhobho owenziweyo zihlangabezana nemigangatho.

4. Ivalve yokulungelelanisa umlinganiselo ongenisiweyo ilungisa ukwenza uxinzelelo oluzinzileyo kwaye luthembekile.

5. I-Corrugator yodidi oluthe tye

6. Ipleyiti esebenzayo ilungelelaniswe macala amathathu.

7. Inkqubo yokukhusela ngokuzenzekelayo iqala kwaye isebenze ibuya xa umbane ucinyiwe.

8. Isikhululo sokuthambisa esizenzekelayo

9. Iibhloko ze-Mold zenziwe nge-alloy ekhethekileyo ye-aluminium kunye neempawu zobunzima obulula, amandla aphezulu, ukunyamezela ukunxiba kakuhle, i-co-efficient encinci yokwandiswa kwe-thermal.

10. Ukupholisa umoya kunye nokupholisa amanzi ukwenzela ukupholisa kakuhle izingundo ezigudileyo ezenza umbhobho ngokukhawuleza.

11. Umatshini wokusika umbhobho we-corrugated uneenzuzo zokuchaneka okuphezulu kwaye akukho thuli.

12. Umgca opheleleyo wamkela inkqubo ye-PLC yokulawula i-micro-computer enokuthi ibonise ngokubonakalayo ukushisa okunyibilikayo kunye noxinzelelo, ukwenza isantya, i-alarm yephutha kwaye iphinde ibe namandla okugcina inkqubo esisiseko.

Iinkcukacha

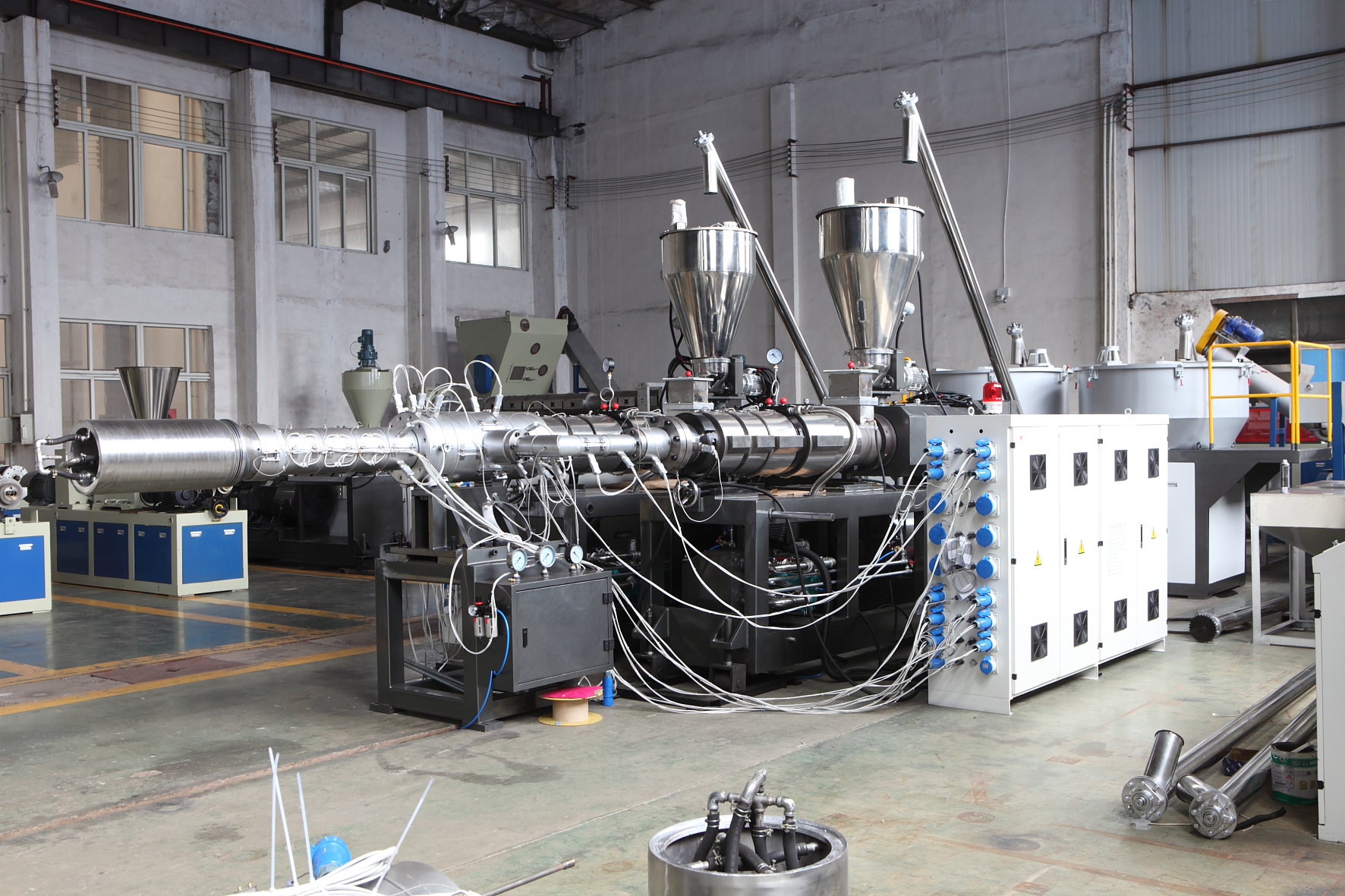

IsiKhohlo esiNye Extruder sePE/PP

Ngokusekelwe ku-33: 1 umlinganiselo we-L / D we-screw design, siye saphuhlisa umlinganiselo we-38: 1 L / D. Xa kuthelekiswa ne-33: umlinganiselo we-1, umlinganiselo we-38: 1 unenzuzo ye-100% yeplastiki, ukwandisa umthamo wemveliso nge-30%, ukunciphisa ukusetyenziswa kwamandla ukuya kuma-30% kwaye ufikelele ekusebenzeni kwe-linear extrusion. I-Adopt L/D ratio 38:1 isikrufu semathiriyeli eseyintombi kunye ne-L/D 33:1 isikrufu semathiriyeli esetyenzisiweyo.

I-Simens Touch Screen kunye ne-PLC

Faka isicelo kwinkqubo ephuhliswe yinkampani yethu, ube nesiNgesi okanye ezinye iilwimi ukuba zibe negalelo kwinkqubo.

Ukwakhiwa kwe-Spiral ye-Barel

Ukondla inxalenye yomgqomo wokusetyenziswa kwesakhiwo esijikelezayo, ukuqinisekisa ukutya kwezinto eziphathekayo ngokuzinzileyo kunye nokwandisa umthamo wokutyisa.

Uyilo olukhethekileyo lweScrew

I-Screw yenzelwe kunye nesakhiwo esikhethekileyo, ukuqinisekisa iplastiki efanelekileyo kunye nokuxuba. Izinto ezinganyibilikiyo azikwazi ukudlula le ndawo yesikrufu.

Isifudumezi seCeramic esipholileyo soMoya

Isifudumezi seCeramic siqinisekisa ubomi obude bokusebenza. Olu yilo kukwandisa indawo apho ukudibana kweheater nomoya. Ukuba nesiphumo esingcono sokupholisa umoya.

Umgangatho ophezulu weGearbox

Ukuchaneka kwegiya kufuneka kuqinisekiswe ibanga le-5-6 kunye nengxolo esezantsi engaphantsi kwe-75dB. Ulwakhiwo olubambeneyo kodwa olunetorque ephezulu.

I-Conical Twin Screw Extruder yePVC

Zombini i-conical twin screw extruder kunye ne-parallel twin screw extruder zingasetyenziswa ukuvelisa iPVC. Ngeteknoloji yakutshanje, ukunciphisa amandla kunye nokuqinisekisa umthamo. Ngokwefomula eyahlukileyo, sibonelela ngoyilo olwahlukileyo lwesijiko ukuqinisekisa isiphumo esihle seplastiki kunye nomthamo ophezulu.

Extrusion Mold

Zombini umaleko wangaphandle kunye nomaleko wangaphakathi zikhutshelwe ngaphakathi kwintloko yokufa. Ijelo ngalinye lokuhamba kwezinto ngaphakathi kwentloko yokufa libekwe ngokulinganayo. Ijelo ngalinye lisemva konyango lobushushu kunye nokupolisha kwesibuko ukuqinisekisa ukuhamba kakuhle kwezinto. Kwakhona die intloko ibonelela ngomoya zixinaniswe phakathi zombini umaleko. Umkhono wokulinganisa usetyenziselwa ukupholisa umaleko wangaphakathi ukwenza umbhobho ogudileyo kunye nosicaba ngaphakathi. Uxinzelelo lwamanzi luhamba ngaphakathi kwimikhono yokulinganisa ukuze ube nesiphumo esihle sokupholisa. Ivacuum yenziwe kumphezulu womkhono wokulinganisa xa uvelisa umbhobho omkhulu odayamitha, qinisekisa ukungqukuva kombhobho ongaphakathi.

Ukwenza uMngundo

CNC machining iqinisekisa imilinganiselo echanekileyo. I-vacuum air duct kunye nomjelo wokupholisa amanzi kunye ne-flow flow cross-section enkulu iqinisekisa ukuzinza, umgangatho ophezulu, kunye nokusebenza ngokufanelekileyo kwemveliso. Imodyuli yemodyuli yi-alloy ye-aluminium ephezulu, ene-conductivity ephezulu ye-thermal, ubunzima obuphezulu, kunye nokumelana nokunxiba okuphezulu. Ubume bemodyuli yamkela inkqubo yokuphosa uxinzelelo oludibeneyo, kunye nokuthungwa kwe-denser kunye nokuzinza okuphezulu kwe-thermal. Unyango lwangaphakathi lwangaphakathi lwemodyuli luphucula amandla kunye nobunzima bemodyuli, eyona nto ihambelana nokubunjwa ngokugqibeleleyo kwee-ripples. I-mold ithatha i-CNC machining ukuqinisekisa ukuchaneka kwayo kunye nokusebenza kakuhle.

Ukupholisa amanzi Umatshini wokubumba

Umatshini wokupholisa wamanzi usetyenziselwa ukubeka kunye nokususa ukungunda okwenziwe ngamalahle, i-vacuum yenziwe ukufunxa umaleko wangaphandle ube ngundonda obhityileyo ukwenza imilo ye-corrugated shape. Ngokuhambisa i-corrugated mold, umbhobho nawo uyakhutshwa kwi-corrugator.

Inkqubo yokuLubrication ezenzekelayo

Lubricate igiya ngokuzenzekela ukwenza ukungunda okuxotshiweyo kuhambe kakuhle.

Ukuhanjiswa kweGear Rack

Indawo yokubeka igeyi ibekwe phezu komngundo owenziwe ngamazinki. Zonke iiracks zegiya zisemva kwe-nitriding kunye nonyango lokufudumeza, ukumelana nokunxiba ixesha elide.

Inkqubo yoLungiso oluPhezulu

Lungisa nge-elektroniki isakhelo esiphezulu sobukhulu obahlukeneyo bokungunda okuxonxiweyo. Ngeentsika ezine, qinisekisa ukulungiswa okuzinzile kunye nokuchanekileyo.

Inkqubo yoLungiso lweTension

Ukulungelelanisa ukuqina kokungunda okuhambayo, yenza ukungunda kuhambe kakuhle.

Ivalufa elinganayo

Ukulawula umoya uzinzile kwaye uchanekile, ukwenza umbhobho olungileyo kunye nemilo yesokhethi.

Inkqubo yokupholisa ngundo

Ngezo zombini iinkqubo zokupholisa kwamanzi kunye nenkqubo yokupholisa umoya, ukuba nesiphumo esingcono sokupholisa, ukwenza umbhobho olungileyo kunye nokukhawulezayo.

UPS Backup Power

Xa umbane usilela, amandla okugcina i-UPS axhasa amandla aya kunika amandla kwi-corrugator ukususa umbhobho kumkhono wokulinganisa. Ukuthintela ukuxinga kombhobho kumkhono wokulinganisa emva kokupholisa kombhobho kunye nokushwabana.

Tshaza itanki laManzi okupholisa

Itanki yokupholisa isetyenziselwa ukupholisa umbhobho ngakumbi.

Ukuthuthwa okuNcedisayo

Ngesixhobo sokutsala esincedisayo, isixhobo sokutsala sibhetyebhetye. Ukutsala umbhobho ngakumbi.

Umgangatho wokutshiza uMlomo

Imilomo yokutshiza esemgangathweni inesiphumo esingcono sokupholisa kwaye akukho lula ukuvaleka bubumdaka.

Isihluzo seTanki yamanzi

Ngecebo lokucoca kwitanki yamanzi, ukuthintela nakuphi na ukungcola okukhulu xa amanzi angaphandle engena.

Umbhobho wokusika umatshini wokusika

Umatshini wokusika umbhobho we-corrugated uchanekileyo ophezulu kwaye akukho thuli.

Isixhobo se-Aluminiyam yokuBamba

Faka isixhobo se-aluminiyam yokudibanisa kwiisayizi ezahlukeneyo zemibhobho. Isayizi nganye kunye nesixhobo sayo sokubambelela, akukho mfuneko yokutshintsha ukuphakama okusembindini xa kubungakanani bombhobho obahlukeneyo.

Inkqubo yongqamaniso

Isikhululo sokusika siqhutywa yimoto kunye ne-inverter. Ngethuba lenkqubo yokusika, isikhululo sokusika sihamba ngokuhambelana ne-corrugator ukuphepha ukuguqulwa kombhobho.

Ukusika imela kabini

Ngeemela ezimbini zokusika kunye, ukuqinisekisa ukuba inxalenye yesokethi inqunyulwe ngokupheleleyo.

Stacker

Ukuxhasa kunye nokothula imibhobho. Ubude be-stacker bunokwenziwa ngokwezifiso.

Ukuxhasa kunye nokothula imibhobho. Ubude be-stacker bunokwenziwa ngokwezifiso.

Ukuze uhambise umbhobho owenziwe kakuhle kwi-stacker, sisebenzisa isinyithi esingenasici esipheleleyo kumphezulu we-stacker.

Ukudibanisa umbhobho kwi-roller, kulula ukuyigcina kunye nokuthutha. Ngokuqhelekileyo isetyenziselwa umbhobho ongaphantsi kobukhulu be-110mm. Yiba nesikhululo esinye kunye nesikhululo esiphindwe kabini sokuzikhethela.

Idatha yoBugcisa

| Umzekelo | Ubungakanani bombhobho(mm) | Extruder | Imveliso(kg/h) | Isantya(m/min) | Amandla ewonke(KW) | Umngundo(izibini) | Inkqubo yokupholisa |

| SGB250 | 90-250 | SJ65 SJ75 | 300 | 1-4 | 150 | 48 | Ukupholisa umoya kunye nokupholisa amanzi |

| SGB500 | 200-500 | SJ75 SJ90 | 600 | 1-4 | 200 | 40 | Ukupholisa umoya kunye nokupholisa amanzi |